Moldex3D Expert module has been extensively used to assist designers in evaluating the proper settings for optimizing processing conditions such as melt temperature, mold temperature, cooling time, flow rate profile, packaging pressure profile.

Now, Moldex3D Expert module provides not only Process Optimization and Design of Experiment (DOE) Analysis, but also Design Optimization. Â Design Optimization of Moldex3D Expert module can achieve optimized runner sizes and gate locations; optimized single/multiple gate(s) location(s) can be automatically achieved with eDesign mesh (True 3D mesh). This powerful function helps users find minimum flow length for each gate, and then achieve balanced flow.

The following tips are essential for optimizing gate locations using Moldex3D Expert Module.

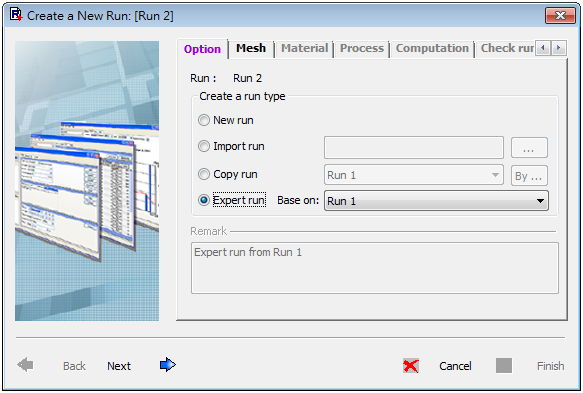

STEP 1. Create an Expert run

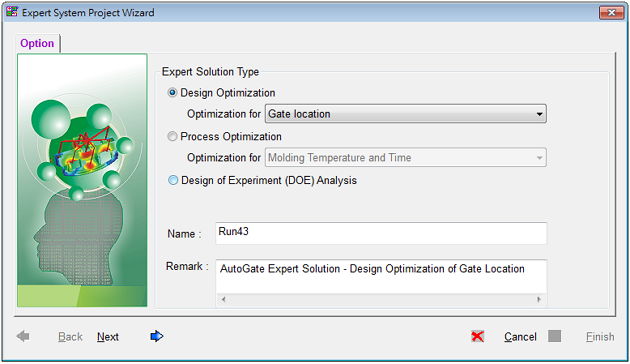

STEP 2. Select Optimization for Gate location in Design Optimization

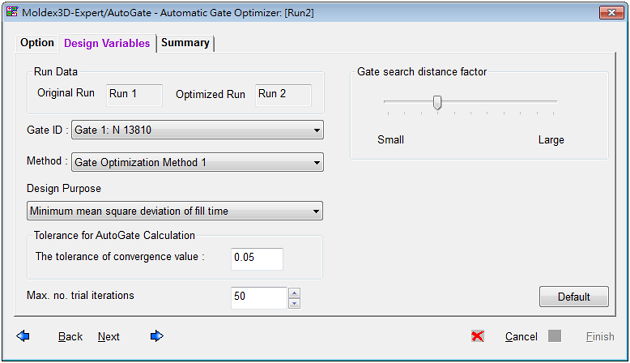

STEP 3. Set Design Variables. The Method, Gate Optimization Method 1, provides efficient iterative calculation to find out the most uniform filling time for specificed gate(s) location(s). The concept is simply given in the Design Purpose, Minimum mean square deviation of fill time; by finding the most uniform filling time from calculation nodes of part model the minimum mean square deviation of fill time is obtained and then the optimized gate(s) location(s) is determined.

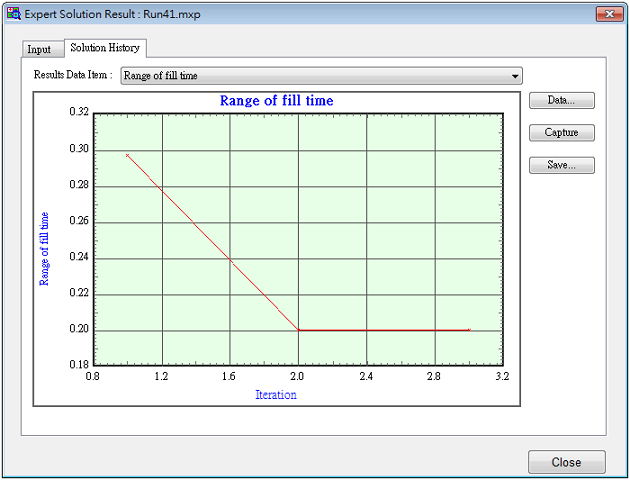

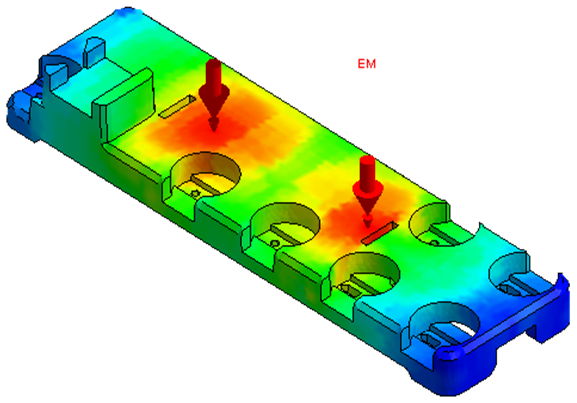

STEP 4. Choose “AutoGate Analysis-AG†as analysis type and then obtain results of optimized gate location. This figure shows the optimization result of filling time, which reflects the minimum mean square deviation of fill time after iterative calculation.

In this figure, the optimized gate locations are identified after the optimization calculation for the original random gate locations.

Brief Introductions of Reaming Shells

Reaming shell is used to couple the drill bit with the core barrel. It is suitable for use on all conventional and wireline core barrel. This product is mainly designed to ream the hole to the standard diameter. It can keep the stability of the core barrel. When the old bit is replaced by the new one, reaming shell can also provide sufficient clearance for the new bit. It can also help to resist the abrasion of the core barrel. This type of diamond tool is physically longer than the standard type. So for the compensation of the difference in reaming shell length, an appropriate inner tube extension is necessary to be used.

Ranging from broken and abrasive to consolidated and non-abrasive formations, reaming shells are all suitable to use.

Features of Reaming Shells

1) Acts as a stabilizer for drill bit.

2) Be set with natural or synthetic diamond.

Our reaming shells enjoy the best quality and most special design in the industry. With several different types, we try our best to satisfy any of your requirements.

Reaming Shell,Reamed Housing,Shell Reamer Set,Adjustable Shell Reamer

JIANGSU XI TEC ENVIRONMENTAL&DRILLING EQUIPMENT COMPANY CO.LTD , https://www.nbxitecdrilling.com